For background on this particular project, please visit Stop Flying By The Seat Of Your Pants.

Situation …

Our client is a fabrication and services company specializing in event marketing. When the business was smaller, it made only one type of product and did not wrap any services around it – and the existing processes and technology handled this very nicely.

Over time, many new and more complex products were successfully added, and then services successfully developed to provide a turn-key solution for its customers, requiring:

- Fabricating various types of base items.

- Printing and affixing graphics on the base items.

- Transporting the finished items of multiple customers to the event.

- Installing the various items.

- Being "on call" for customers at the event.

- Taking down the items, sending certain ones to the next event, and warehousing the remainder.

Opportunity …

The company's processes and technology did not change to accommodate the new realities of volume and complexity. They did nothing to make the turn-key processing for multiple customers at multiple events more efficient and effective.

Our client identified several key problems:

- Taking on more business was virtually impossible.

- Planning and scheduling was difficult, because employees had no visibility of upcoming work, since most information was stored in Excel.

- Fixing mistakes made internally, especially products made with preliminary graphics and not the final customer-approved ones, was costly.

- Billing opportunities were likely missed because customer requests for product changes after their final approval, or for additional services outside the scope of work, were not being tracked.

The company's owner estimated that the last two problems could be costing his company $100,000 annually.

Solution …

Todd Herman Associates was retained to analyze existing processes, recommend improvements, gain consensus for the recommendations, and implement the revised processes using a custom workflow automation application.

Gaining consensus was challenging, because each manager had devised his own process and technology – typically, Excel worksheets – to estimate, track, and bill products and services. Furthermore, managers in the production and service delivery sides of the business used "Customer," "Event," "Order," and "Project" differently. Our consultant achieved consensus on the future processes and on a common vocabulary. Once everyone agreed on these foundational concepts, application design and development could begin.

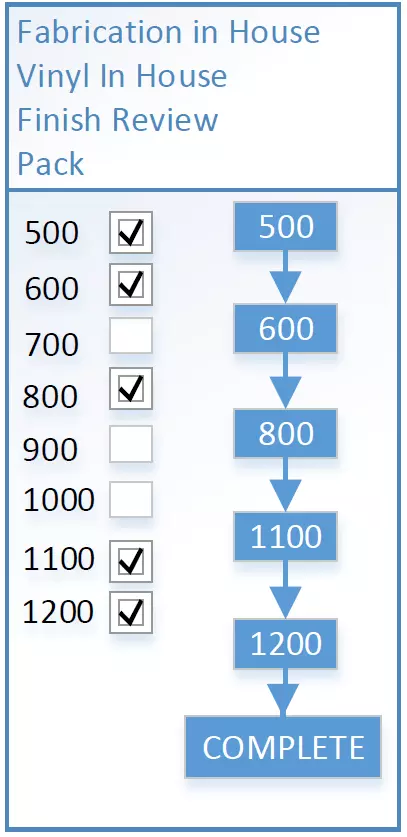

Flexibility in defining routings of the products was critically important, as all items are made to order. Thus, the application allows a manager to pick all the relevant processing, then provides visibility and accountability of items in each operation's queue.

In working to error-proof the process, our consultant designed safeguards into the document management process, so that all versions of a design or graphic are stored and clearly labeled, and only the customer-approved versions were available for production managers and operators.

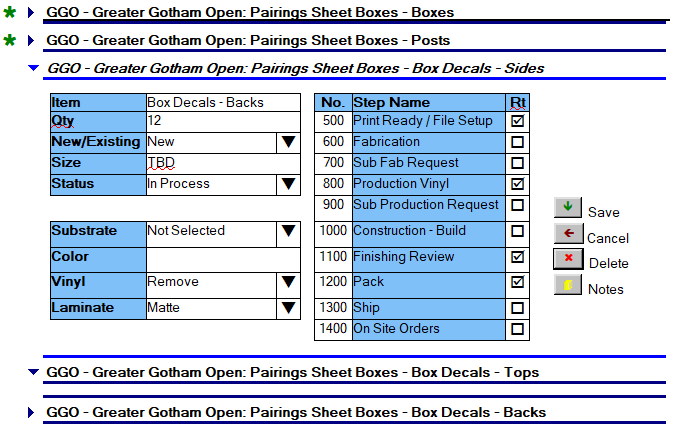

Above, this screen shows five components to be fabricated and assembled to make one finished item. Each component has its specifications and user-defined workflow routing, as shown for the third component. Specifications and routings for the first two components have been defined and submitted to Fabrication (denoted by the green star).

|

|

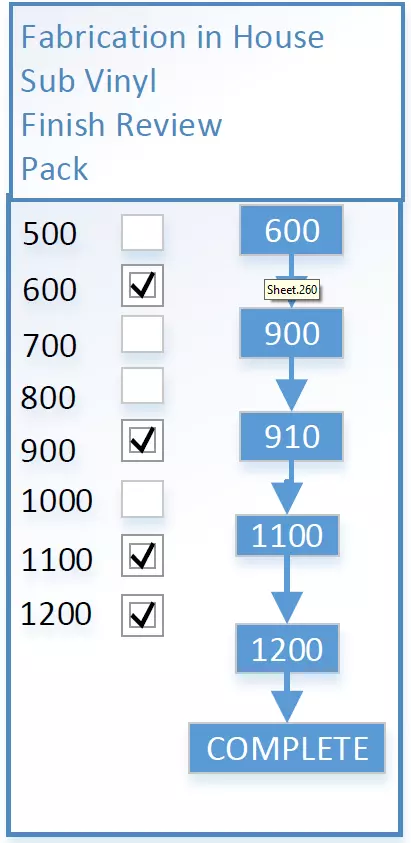

Above, other types of components route through different operations. Sub-routes, such as 910, are needed for Production, yet not for planning.

Results and Benefits …

With production ramping up to support events beginning in the first quarter and continuing through the end of October, our client can now see the status of every item associated with a customer, event, order, and project. The shop is making products using final graphics, without having to find them on a network drive and guess which one was approved by the customer. Rework is being reduced, and any that now occurs can be analyzed for root causes.

Work is flowing more smoothly, and bottlenecks are being quickly identified and addressed. Everyone from the president down sees exactly what needs to be done, by whom, and by when. Users also see the efficiencies in store for this year’s billing process and next year’s event rollovers.

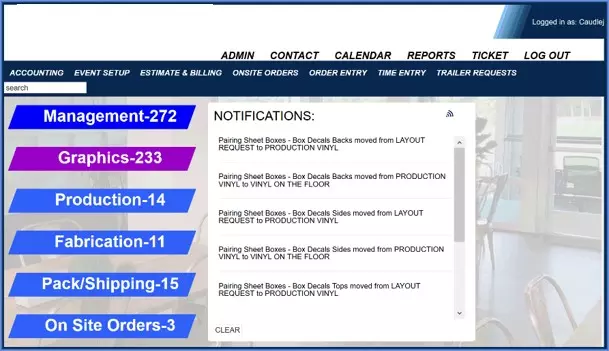

Above, the application's home page. Each department is responsible for specified workflow steps (left pane). The numbers following department names indicate how many components are currently in the department. System-generated notifications (center pane) are displayed for events or steps the user has chosen to follow.

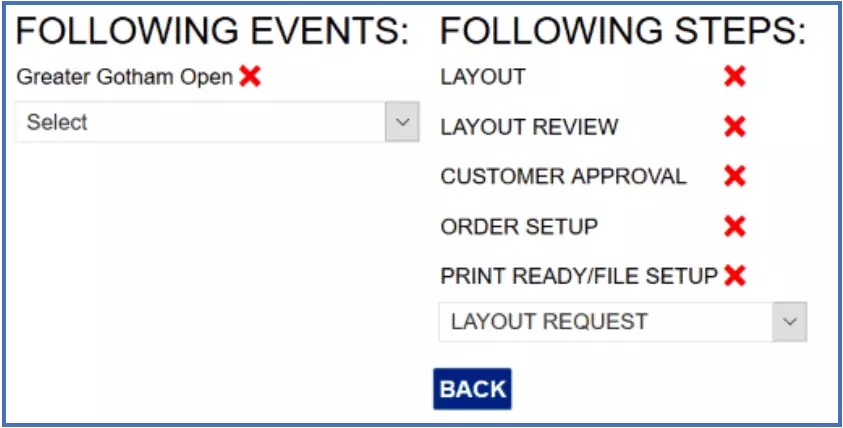

Above, pressing the RSS Feed icon (top-right of the Notifications pane) allows the user to select events and steps to follow.

Conclusion …

Would you like your operations to run more smoothly, more efficiently, and with fewer mistakes? If so, perhaps we can do for you what we did for this client. Please call or email us, and let's discuss whether our capabilities would be a good fit for your needs.