Todd outlines how you can get "Better – Cheaper – Faster" all at the same time, by describing a concept called "The Process Triangle."

After writing over 120 monthly e-updates and – prior to electronic versions – 38 print updates, it's sometimes hard to find a topic I haven't already covered, or to find a new angle on a previously-covered topic. While I have written before on how to simultaneously improve quality, cut costs, and reduce cycle time of a process (see "Buy One, Get Two Free: A Business Fable"), I've never written about the underlying concept, which I first articulated about 18 months after my "Buy One, Get Two Free" article.

I call that concept, "Todd's Hypothesis," which I define as:

| It is impossible to ... | Reduce Process Cycle Time | or ... |

| Improve Process Quality | without also achieving ... | |

| Lower Process Cost | as a natural by-product. |

Basically, I'm saying that these three benefits – Reduced Cycle Time, Improved Quality, and Lowered Cost – are equivalent to one another. Let me give you a moment to let that statement sink in.

"The Iron Triangle" of Project Management

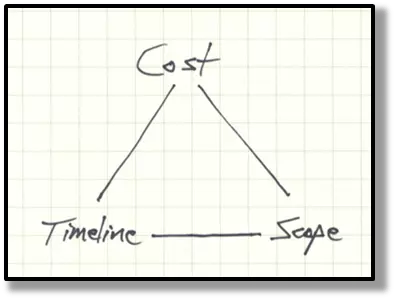

To better understand WHY these three benefits are equivalent, let's first talk about a concept called "The Iron Triangle" which I'd first heard about in Project Management. In that context, there are three attributes a Project Manager (PM) can measure – the Cost, Timeline, and Scope of a project. To a PM, "Scope" can be informal expectations for a project, or formal expectations defined in its Charter, Scope, or Specifications documents.

Here's what this looks like:

When a project slips on its target end date – and there are very few projects where this does not slip at least a little – the PM has to work with the Project Sponsor to determine what has to give. That's why it's called "The Iron Triangle" – something ALWAYS has to give.

- To hit the desired Cost, the Timeline or Scope (and maybe both) will have to change.

- To hit the desired Timeline, the Scope or Cost (and maybe both) will have to change.

- To hit the desired Scope (Specifications), the Timeline or Cost (and maybe both) will have to change.

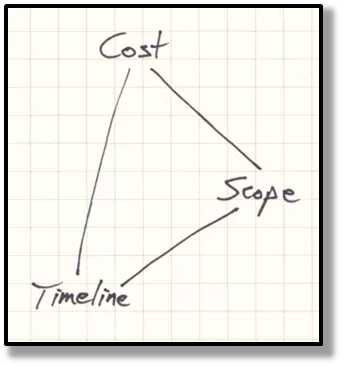

When you begin a project, you have every intention of hitting all three goals – I've drawn that above as an equilateral triangle. Once something slips, the triangle gets shifted; and is no longer equilateral. For example, hitting the Cost target, while maintaining the desired Scope, pushes out your Timeline.

Visually, your triangle now looks like this:

"The Process Triangle" of Cost, Cycle Time, and Quality

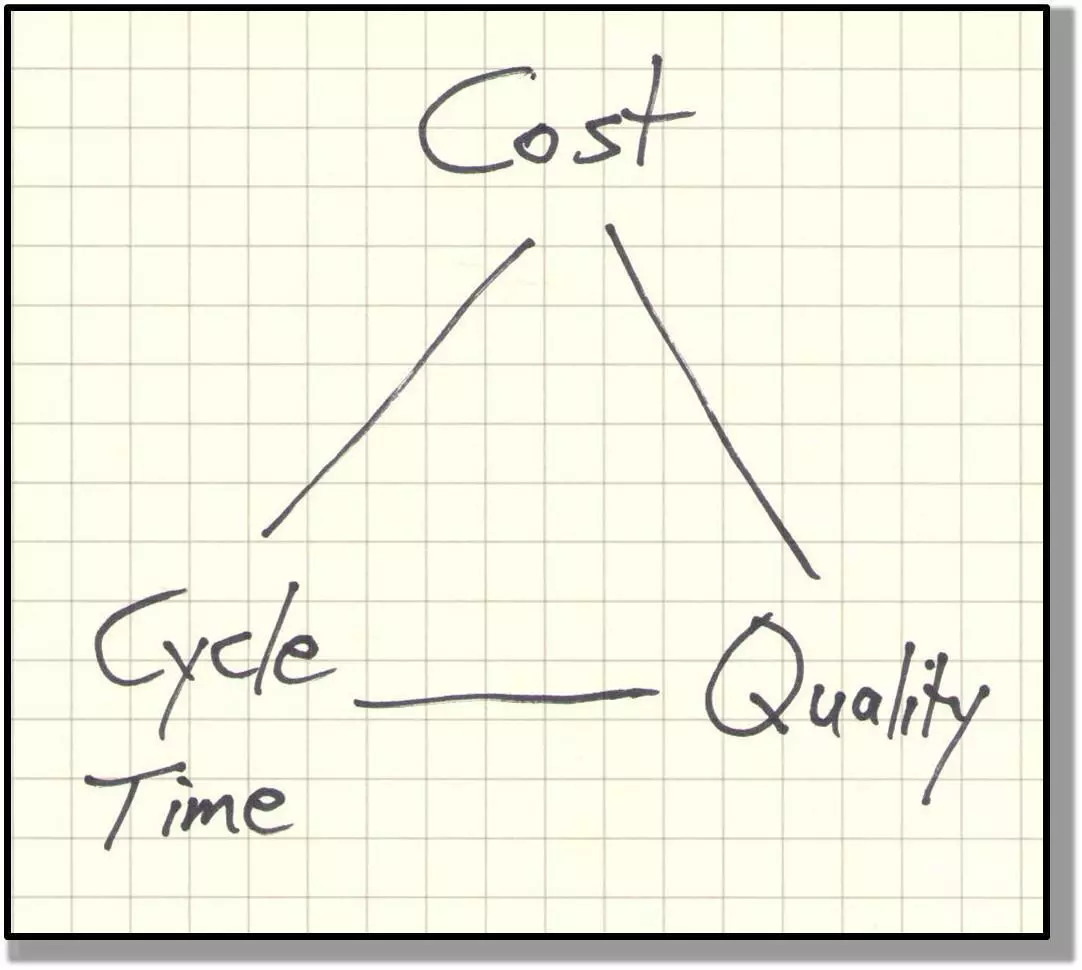

Because we work with clients to improve processes by using technology, I've adapted the triangle concept to fit the attributes of a process. A process can be measured by its:

- Cost – The amount of financial resources needed to complete a process.

- Cycle Time – How long it takes, from start to finish, to complete a process.

- Quality – How well the process conforms to expectations, where expectations typically exist for BOTH the process itself AND the output of a process (say, a widget or a legal document).

Visually, these measures are:

One key implication of all this – because "Todd's Hypothesis" says that Cost, Cycle Time, and Quality are equivalent – "The Process Triangle" will ALWAYS maintain its equilateral shape!

How can all three attributes – Cost, Cycle Time, and Quality – be achieved simultaneously? Put another way, how can you get "Better – Cheaper – Faster" all at once?

Errors Gum Up Cost, Cycle Time, and Quality at the Same Time!

The answer depends on this insight – something links these three attributes together. What links all three? Errors. Here's a quick example:

Andrew is supposed to fill out a form and send it to Betty. When she gets it, she says, "I can't believe it – Andrew did it again, leaving out a key piece of information I need to do my work." Then Betty will either send the form back to Andrew and have him fix his mistake, or contact Andrew to get the information she needs and enter it into the form herself.

Here's how Andrew's error impacted ...

- Quality – Incomplete information indicates low quality in Andrew's completion of the form.

- Cycle Time – The time incurred to get the correct information into Betty's hands was more than what was required if Andrew had done things right the first time.

- Cost – Both Betty and Andrew spent time fixing Andrew's mistake, and there is obviously a cost associated with each person's time.

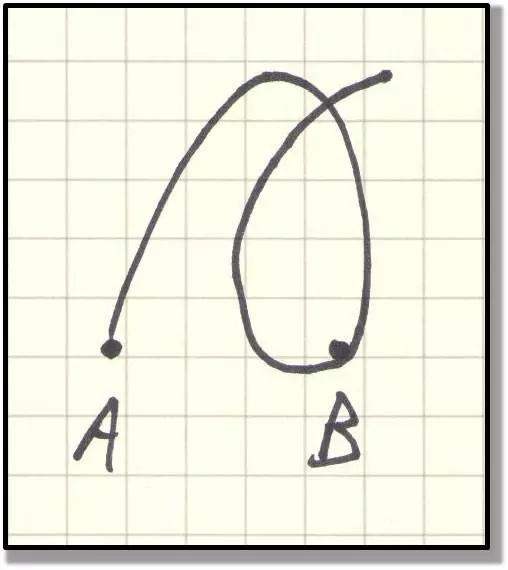

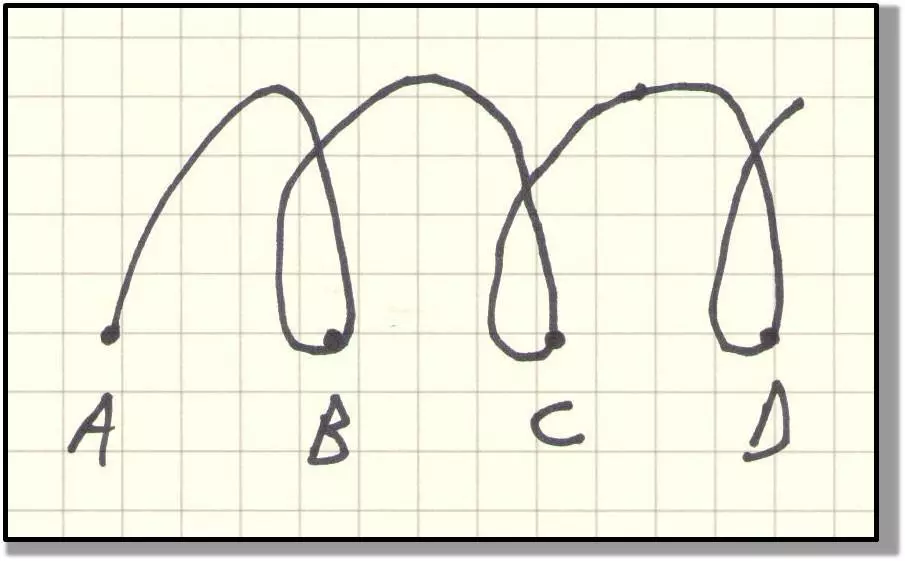

When an error occurs – either in the process itself or in its output – rework is incurred to fix the problem. By definition, an Error reduces the Quality of a process or its output, and the related Rework drives up Cost and lengthens Cycle Time. Visually, the single error in our Andrew and Betty example looks like this:

When a process has multiple errors, it might resemble this:

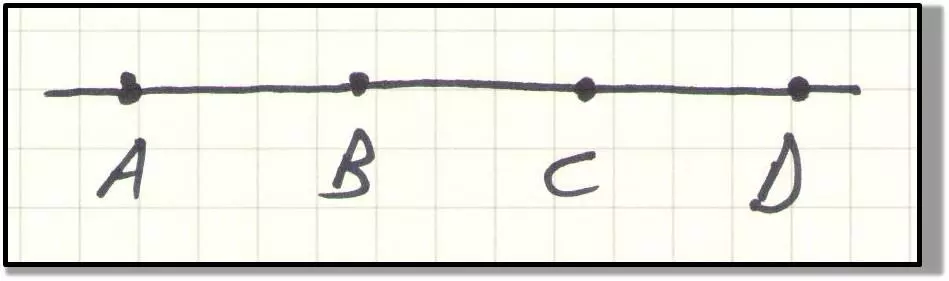

A process with no errors might be this:

Errors and associated rework make a process look like a "Slinky," while an error-free process is a "straight line."

Look for the conclusion of this article in the next couple months. For now, begin looking at your business and operations, and apply the insights from this article to them.

If you find your business and operations contain more errors than you'd thought, call or email me anytime to discuss ways to get rid of them.

Sincerely,

Todd L. Herman